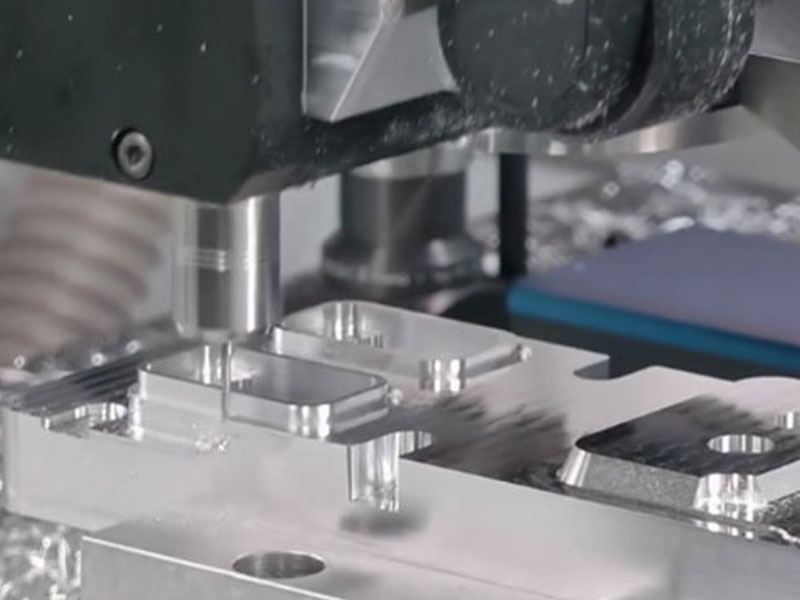

Precision stamping parts are manufactured through a series of stamping processes such as stamping, extrusion, rolling, welding, and cutting, which are difficult to manufacture. In order to meet produc...

+86-0769-88028028

English

English