+86-0769-88028028

Attention Points for Turning in Machining

1. What is turning process?Turning is a process in which the shape and size of blanks, which are fixed on lathes, are changed by using the rotation of the workpiece and the linear or curved motion of ...

More+

Attention Points for Turning in Machining

1. What is turning process?Turning is a process in which the shape and size of blanks, which are fixed on lathes, are changed by using the rotation of the workpiece and the linear or curved motion of ...

More+

Several Methods to Control Chip Breaking in Turning in Machining

In the turning in machining, when the continuous band-shaped chips are produced, it is not only easy to scratch the surface of the workpiece and damage the cutting edge, but in serious cases also thre...

More+

Several Methods to Control Chip Breaking in Turning in Machining

In the turning in machining, when the continuous band-shaped chips are produced, it is not only easy to scratch the surface of the workpiece and damage the cutting edge, but in serious cases also thre...

More+

The Type and Design Idea of Coil Spring

Types of coil spring1. Compression spring is one of the most applied springs.Helical compression springs usually have round sections with constant pitch and fall into categories as cylindrically helic...

More+

The Type and Design Idea of Coil Spring

Types of coil spring1. Compression spring is one of the most applied springs.Helical compression springs usually have round sections with constant pitch and fall into categories as cylindrically helic...

More+

Safety Technology of Turning

Turning is one of the most widely used processes in machine manufacturing industry. The number of lathes and personnel is large. The range of processing is wide and the tools and fixtures used in the ...

More+

Safety Technology of Turning

Turning is one of the most widely used processes in machine manufacturing industry. The number of lathes and personnel is large. The range of processing is wide and the tools and fixtures used in the ...

More+

Treatment of Spring Compression

1. The problem of compression springsAfter the spring is formed, it generally needs to be subjected to low temperature stress removal annealing or bluing treatment at 220-330 ℃, or according to the r...

More+

Treatment of Spring Compression

1. The problem of compression springsAfter the spring is formed, it generally needs to be subjected to low temperature stress removal annealing or bluing treatment at 220-330 ℃, or according to the r...

More+

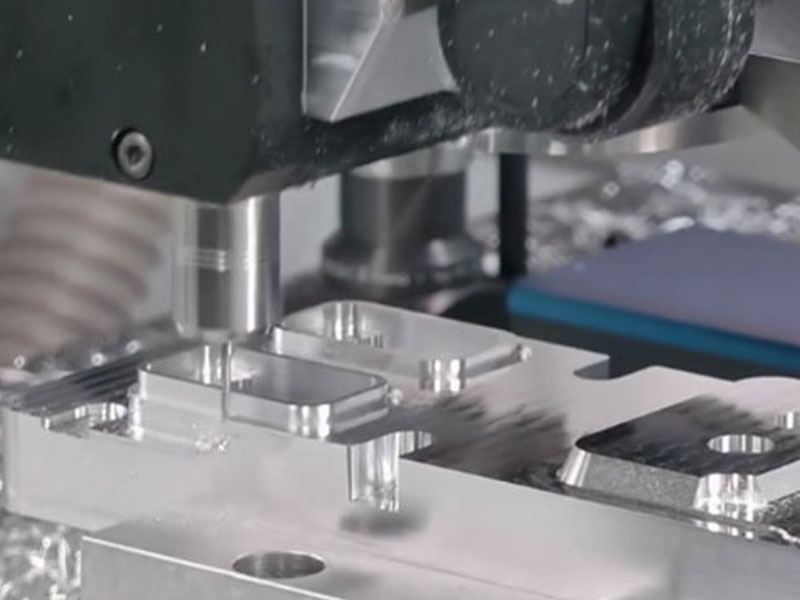

What Are the Advantages of Precision Stamping and Processing Precautions

Ⅰ. Compared with traditional methods, precision stamping has the following advantages:1. Precision stamping has high production efficiency, simple operation, and easy realization of mechanization and...

More+

What Are the Advantages of Precision Stamping and Processing Precautions

Ⅰ. Compared with traditional methods, precision stamping has the following advantages:1. Precision stamping has high production efficiency, simple operation, and easy realization of mechanization and...

More+